Industrial Engine Failure: How Connecting Rod Repair Services Save Millions

Connecting rod failures cost industrial operations millions in unexpected downtime and emergency repairs. These critical components link your piston to the crankshaft, converting explosive combustion energy into the rotational power that drives your equipment. A single failed rod can destroy an entire engine in seconds, turning a manageable maintenance issue into a catastrophic equipment loss.

Industrial connecting rods face brutal operating conditions. Extreme pressure spikes and temperature swings push these components beyond normal limits, especially in heavy-duty applications. Modern engines demand more power from lighter components, creating stress levels that would have been unthinkable just decades ago. The result? Connecting rod breakdowns rank among the most devastating engine failures in industrial settings.

Poor-quality or worn connecting rods create a domino effect of destruction. Engine performance drops dramatically as compression disappears. Fuel efficiency plummets while maintenance costs skyrocket. Mechanical breakdowns follow, often leaving equipment completely inoperable when you need it most.

Weldangrind, Edmonton's leading engine rebuilders, know these components endure punishing stress cycles, particularly in high-performance industrial engines. Their professional industrial engine repair in Edmonton targets rod failures before they spread damage throughout your engine. Expert engine block rebuilding restores these vital components using precision techniques that prevent extensive secondary damage. Their engine machine shop delivers specialized services that extend engine life while protecting your operation from the crushing costs of complete engine replacement.

How Connecting Rod Failure Disrupts Industrial Engines

Connecting rod breakdowns trigger a cascade of destruction that spreads throughout industrial engines. These components endure extreme mechanical stress while transferring explosive forces from pistons to crankshafts. When they fail, the damage rarely stops there.

Loss of compression and power output

Rod failure destroys engine compression instantly, creating sudden power loss that can shut down entire operations. Connecting rod collapse ranks among the most devastating causes of catastrophic engine failure. These components face a brutal double assault - compression forces during combustion followed by tension forces from inertial loads, creating relentless high-cycle fatigue conditions. This constant stress cycling makes rods vulnerable to buckling, bending, and torsional failures from mechanical overloads.

The power loss happens without warning. Engines lose their ability to maintain proper combustion chamber pressure, often rendering equipment completely dead rather than merely struggling. Equipment operators know this truth: connecting rod failure means immediate shutdown, not gradual performance decline.

Crankshaft damage from rod breakage

A broken rod whirling inside the crankcase creates mayhem. Shattered connecting rods punch through engine blocks, destroying oil pressure systems and triggering overheating that seizes entire engines. Metal fragments scatter throughout the engine, destroying precision surfaces that took years to properly break in.

Rod failures typically start from these common causes:

- Bearing seizures when oil starvation or improper clearances create friction

- Material fatigue beginning at surface imperfections

- Excessive tensile loads during high RPM operation

- Mechanical overload from abnormal combustion events

Each broken fragment becomes a projectile that damages everything in its path.

Downtime costs in heavy-duty applications

Industrial equipment downtime creates financial bleeding that accelerates quickly. Heavy machinery downtime costs swing dramatically based on equipment type and repair complexity, potentially reaching thousands of dollars per hour. Every hour of dead equipment represents vanished productivity, lost revenue, and missed opportunities.

Smart operators throughout Edmonton turn to Weldangrind’s specialized connecting rod repair services to stop these losses before they start. Their experienced engine rebuilders recognize that preventative maintenance through skilled engine block rebuilding costs far less than emergency repairs. Their expert engine machine shop focuses on industrial engine repair services designed to catch these critical problems before catastrophic failure strikes.

Early Warning Signs of Connecting Rod Damage

Smart operators catch connecting rod problems before they destroy entire engines. Know these warning signals, and you'll contact repair services while fixes still make financial sense rather than facing complete equipment replacement.

Engine knocking and vibration patterns

Ever heard an engine sound like it's trying to punch its way out of the block? That's rod knock talking. This deep, rhythmic tapping noise gets louder as engine speed climbs. Unlike other engine sounds that come and go, rod knock stays consistent - idle speed creates a loud ticking or smacking sound that accelerates dramatically when you hit the throttle. Temperature changes won't make it disappear like some harmless startup noises.

Vibration analysis reveals problems weeks before they become disasters. Industrial equipment operators rely on crosshead vibration monitoring to spot connecting rod wear or looseness long before catastrophic failure hits.

Oil contamination from metal debris

Your oil filter tells stories about internal engine health. Shiny metal particles during oil changes mean immediate consultation with Weldangrind’s engine block rebuilding specialists in Edmonton. Different metals point to specific problems - aluminum bits suggest piston issues, while magnetic iron filings usually mean connecting rod bearing wear.

Connecting rod bearings shed metal debris as they deteriorate, circulating destructive particles throughout your engine oil system. This contaminated oil damages other components, creating a destructive chain reaction. Check oil filters routinely for these early bearing wear indicators.

Thermal stress indicators in high-load engines

Heavy-duty engines broadcast thermal stress warnings before connecting rod failure strikes. Oil pressure drops often signal bearing problems since worn bearings create larger clearances and reduce system pressure. Dashboard warning lights for oil pressure or engine temperature typically illuminate before catastrophic breakdown.

How Repair Services Prevent Engine Replacement

Why replace an entire engine when expert repair can restore your connecting rods for a fraction of the cost? Weldangrind’s professional connecting rod repair services in Edmonton deliver advanced solutions that save industrial engines from expensive replacement. Severe damage doesn't automatically mean total loss - specialized repair techniques restore function while protecting your budget.

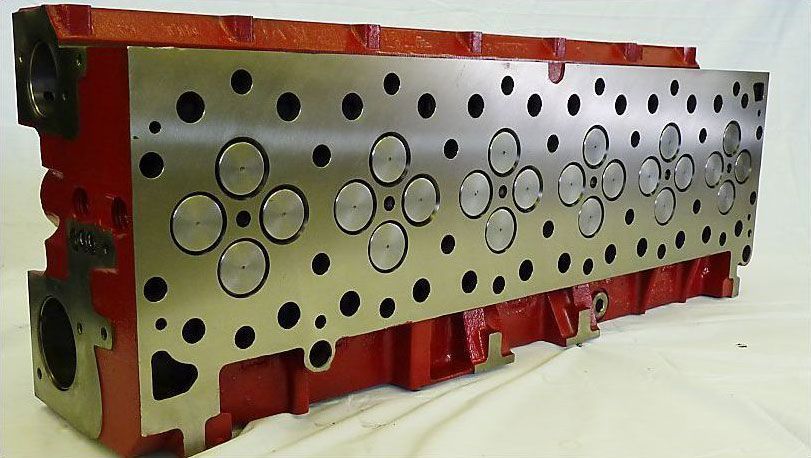

Crack detection and non-destructive testing methods

Smart repairs start with thorough inspection. Magnetic Particle Inspection (MPI) reveals cracks invisible to the naked eye by magnetizing connecting rods and applying iron oxide particles. These particles gather along fracture lines, creating clear patterns under ultraviolet light that expose hidden damage.

Non-ferrous materials need different approaches. Dye penetrant testing uses colored liquids that seep into surface defects. After developer application, these flaws become clearly visible. Ultrasonic testing goes deeper, sending sound waves through components to detect internal problems before they cause catastrophic failures.

Re-machining vs. replacement: cost-benefit analysis

The numbers tell a compelling story. Reconditioned connecting rods cost roughly one-fourth the price of new manufacturer parts while delivering equivalent performance standards. The reconditioning process involves thorough cleaning, magnafluxing, and precision machining that restores critical dimensions to factory specifications.

Shot peening changes the game completely. This specialized surface treatment increases connecting rod fatigue life up to 1000% by relieving internal stresses that cause premature failure. Quality control departments verify every dimension against manufacturer specifications using independent testing tools - no shortcuts, no compromises.

Weldangrind, the best engine rebuilders in Edmonton, know when repair makes sense and when replacement becomes necessary. Their expertise prevents costly mistakes that plague inexperienced shops.

Cost Savings from Timely Connecting Rod Repairs

Money talks in industrial operations. Smart maintenance decisions separate profitable businesses from those struggling with unexpected repair bills. Early connecting rod repairs create financial advantages that ripple through your entire operation.

Avoiding full engine block rebuilding in Edmonton

A single failed connecting rod triggers catastrophic damage that destroys engine blocks, crankshafts, and surrounding components. Early intervention stops this destruction cold. The math speaks for itself - connecting rod repair costs a fraction of complete engine reconstruction. The gap between targeted repairs and total rebuilds reaches tens of thousands of dollars per engine.

Smart operators recognize this pattern. Address the problem early, save substantial money later.

Reducing downtime in commercial fleets

Fleet downtime costs hit hard and fast. Commercial operators face significant daily losses per vehicle. Small operations struggle under these expenses quickly. Weldangrind, Edmonton's top engine rebuilders, know that planned maintenance beats emergency repairs every time. Scheduled service creates predictable costs instead of financial disasters.

Role of our engine machine shop in cost control

The Weldangrind Group balances quality with smart spending. Their industrial engine repair experience enables precision work that extends component life without replacement costs. This expertise protects your budget while maintaining equipment reliability.

The Bottom Line

Connecting rod problems don't fix themselves. The longer you wait, the more expensive repairs become. Smart industrial operators know this truth: early intervention saves both money and equipment.

Professional repair services deliver results that make financial sense. Advanced inspection techniques catch problems weeks before catastrophic failure strikes. Specialized machining restores connecting rods to factory specifications for thousands less than replacement costs. The math works in your favor when you act quickly.

Edmonton's industrial operations depend The Weldangrind Group’s expert engine machine shop for specialized connecting rod services. Their expertise prevents component failures from spreading destruction throughout expensive equipment. Quality maintenance costs less than emergency replacements - and keeps production running smoothly.

Think about it this way: would you rather schedule planned maintenance or deal with unexpected shutdowns during your busiest season? Professional connecting rod repair services offer the predictable solution that protects industrial engines while preserving operational efficiency.

The choice becomes clear once you understand the stakes. Address connecting rod issues promptly through professional connecting repair services. This approach maintains peak engine performance while avoiding the substantial costs that follow catastrophic failures.